Stainless steel drainage basins

- individually manufactured according to customer requirements

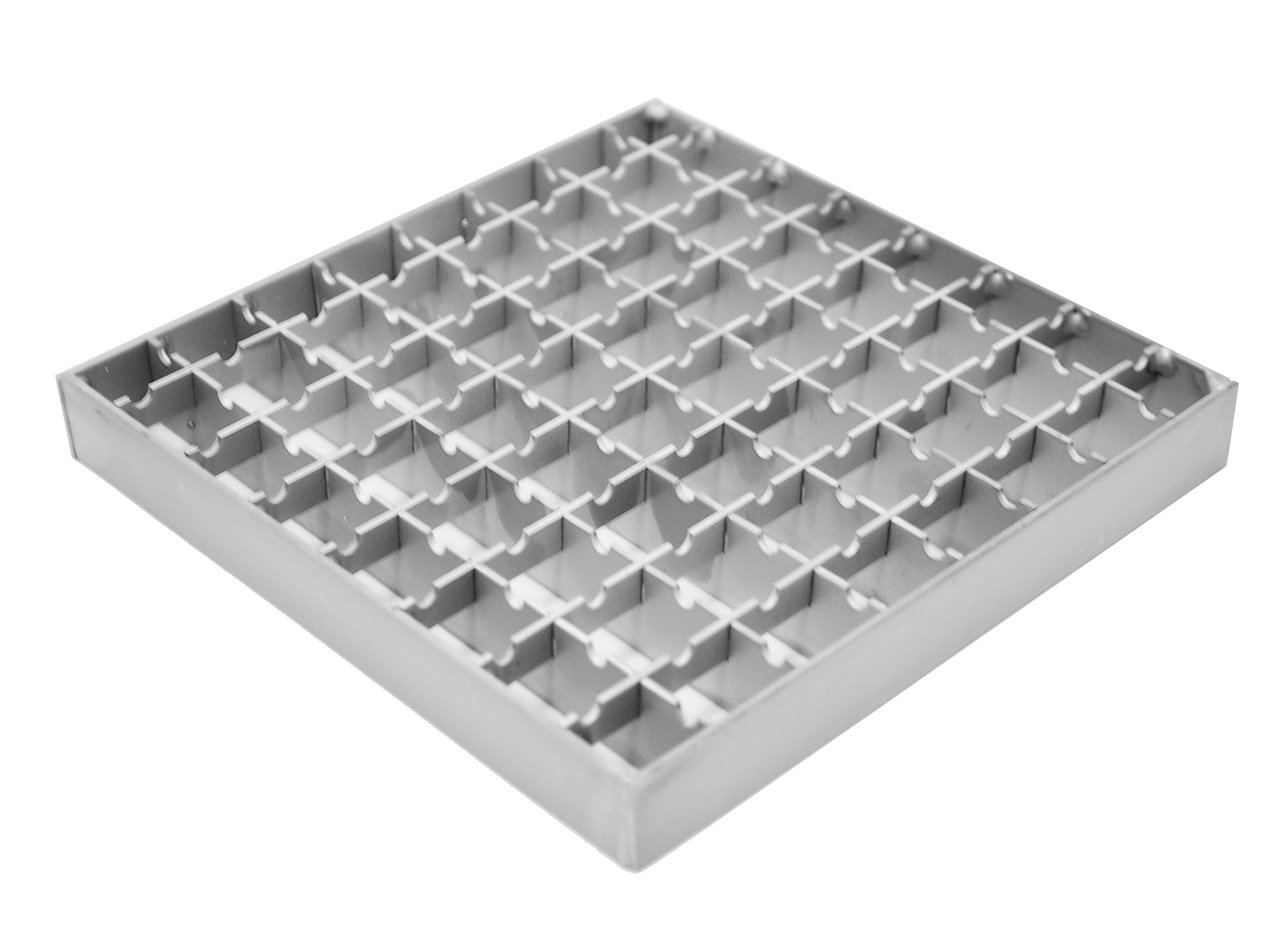

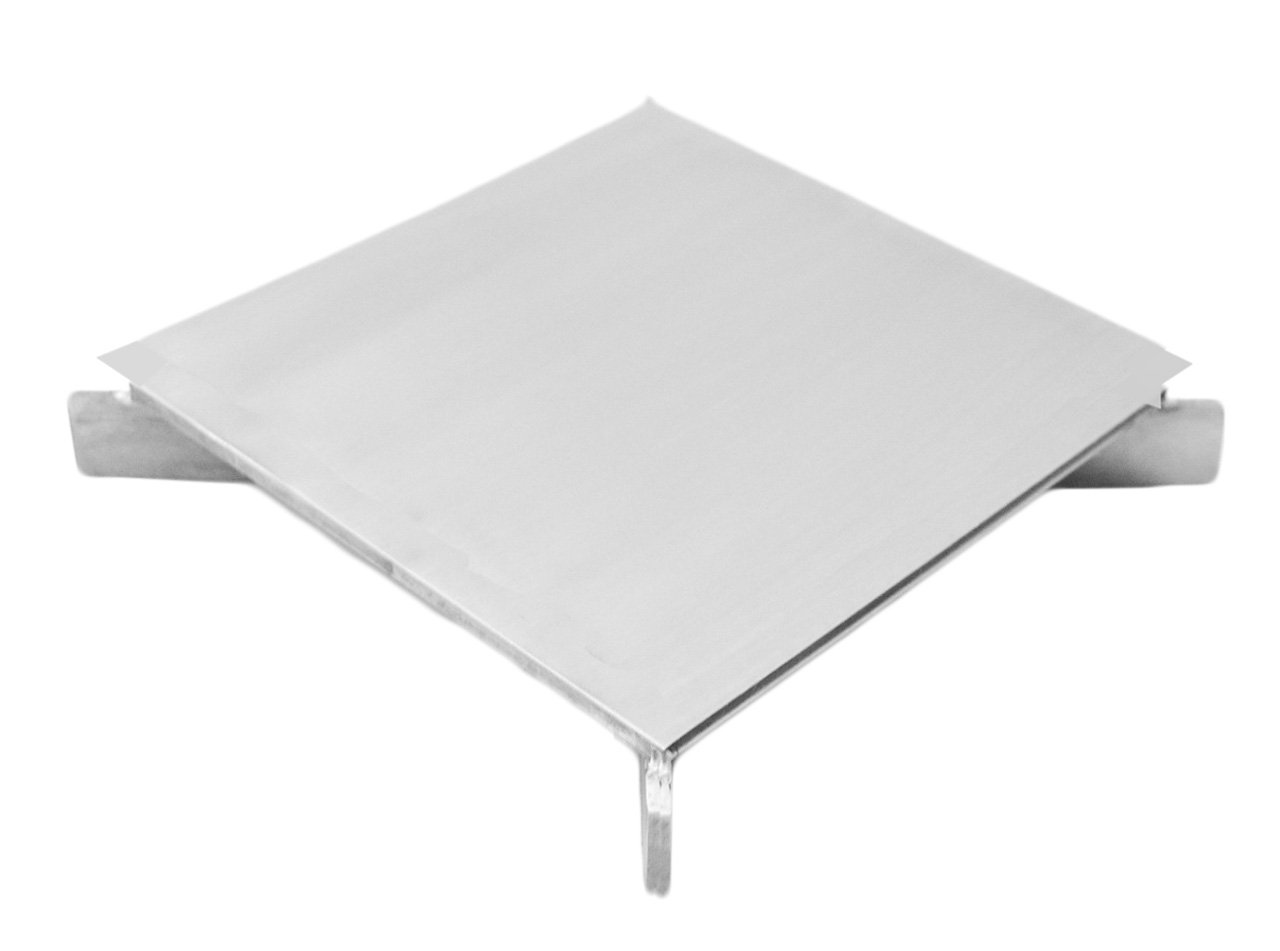

- 3 covers to choose from: plate cover 25x10mm, plain ladder grating 25x8mm, slip resistant mesh grating 25x3mm

- easy instalation

- material: stainless steel V2A or V4A

- including mounting brackets and concrete straps

- OPTIONAL:

- high adhesion layer epoxy+sand to the difficult substrate

- screwed cover (for all dedicated types)

- flange with earthing

- adhesive flange or perforated processing flange

Desription

A drainage tube can be constructed with a floor drain and drainage channel, forming a complex drainage system. We also offer a special version of the tubs such as disinfection tub. Our drainage pans can be made as one-piece or two-piece, where the top is height-adjustable. The odor trap and the dirt basket of the product are removable. This facilitates cleaning and prevents clogging.

Features

The Stainless steel basin BK_X + Y is manufactured according to customer dimensions. We can produce any size according to customer requirements. A tub contains a brace profile and an integrated dirt catcher basket. The odor trap is removable. The product can be made of stainless steel (1.4301 V2A) or acid-resistant stainless steel (1.4571 V4A). The cover is selectable. We offer 3 types of covers: plate cover, plain ladder grating, slip resistant mesh grating.

Application

Our drainage systems can be used in any installation situation and can be manufactured according to the customer's specifications. In our offer you will find a special version of the drainage basins- Disinfection basins, which are suitable for the disinfection of soles, wheels and wheels. The drainage basins can be used in the food industry as well as in the pharmaceutical industry. We also offer acid-resistant V4A stainless steel tubs that meet high hygienic requirements.

Technical description

One-part drainage basin vertical

| | One part basin vertical |

|---|---|

| X [mm] | According to customer requirements |

| Y [mm] | According to customer requirements |

| H [mm] | min. 210 |

| h [mm] | min. 70 |

| D [mm] | 168/250/350 |

| DN [mm] | 75/110/160 |

| AT [mm] | min. 45 |

| ET [mm] | According to customer requirements |

One part basin Horizontal

| | One part basin Horizontal |

|---|---|

| X [mm] | According to customer requirements |

| Y [mm] | According to customer requirements |

| H [mm] | min. 220 |

| h [mm] | min. 70 |

| D [mm] | 165/250/350 |

| DN [mm] | 75/110/160 |

| AT [mm] | min. 45 |

| ET [mm] | According to customer requirements |

Two-part drainage basin vertical

| | Two-part drainage basin vertical |

|---|---|

| X [mm] | According to customer requirements |

| Y [mm] | According to customer requirements |

| Hg [mm] | 50-160 |

| H [mm] | min. 150 |

| h [mm] | min. 70 |

| D [mm] | 195/250/350 |

| DN [mm] | 75/110/160 |

| AT [mm] | min. 45 |

| ET [mm] | According to customer requirements |

Two-part drainage basin horizontal

| | Two-part drainage basin horizontal |

|---|---|

| X [mm] | According to customer requirements |

| Y [mm] | According to customer requirements |

| Hg [mm] | 50-160 |

| H [mm] | min. 220 |

| h [mm] | min. 70 |

| D [mm] | 195/250/350 |

| DN [mm] | 75/110/160 |

| AT [mm] | min. 45 |

| ET [mm] | According to customer requirements |

Covers

Slip resistant mesh grating

Non-slip surface

Plain ladder grating

For heavy loads

Plate cover

Aesthetic appearance