Drainage technology - optional finishing

- Flange, wall flange or perforated flange

- Epoxy resin with sand or other filling

- Body of channel with epoxy resin + sand surface

- Whole body of epoxy resin + sand surface

- Custom outlet

- Custom covers

- Adapting to mounting situation

- Erdungslaschen

- Custom heights

- Mounting cover plates for clean instalation

- Channels with double reinforcement profile

- Channels with full metall profile reinforcement

Custom solutions for stainless steel drainage technology

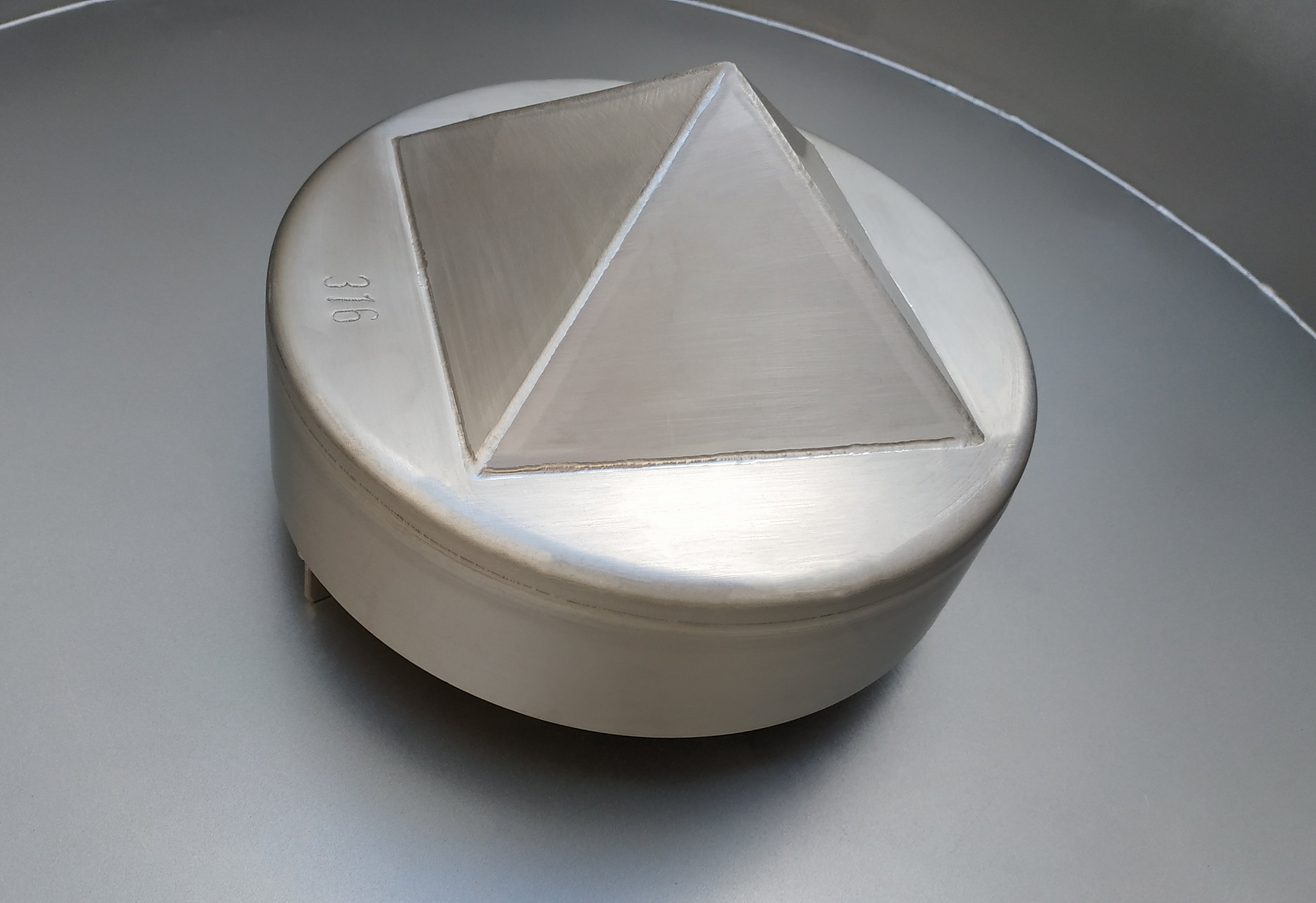

Epoxy resin flange finishing

The most common optional finish chosen by customers is epoxy resin flange finishing. To get high adhesion layer we offer epoxy resin+sand which is a solution for the difficult substrate. Epoxy resin with sand ensures that the channel will engage exactly with the ground - concrete or other type of floor finish. Use of resin ensures high resistance of the connection between stainless steel and the concrete floor. This is very important in investments in industry where the project is significant and the place of drainage application is very specialized.

To get a full filling of the rant edges of the channels and floor gullys, we offer a mix of quartz sand and epoxy resin. The resin in combination with sand is lighter and more resistant to impacts and fills the edge of the product exactly, thus providing a highly adhesive layer for connection with the concrete floor.

Perforated flange

We also offer perforated flange. Holes in the flange allow a strong and reliable connection of stainless steel with concrete. Thanks to the holes, air bubbles can get out of the concrete, which is very important in the context of joint resistance and assembly situation in highly specialized production areas. This also ensures durability if the concret mix is selected appropriately.

Custom outlets

For a customer guidelines we are able to use custom outlets solutions like: angle outlet pipe, outlet pipe welded at an angle, reduction pipe, custom connection pipe, extending outlet pipe, extended outlet pipe.

Channels adapted to be welded at the assembly place

We also offer channels adapted to be welded to another section at the assembly place. That is solution if channel is to long ot to heavy to transport it in one piece. For this kind of channels we are welding flat bars on the gutter walls - they are helpfull in setting up the channels in the right level and place.